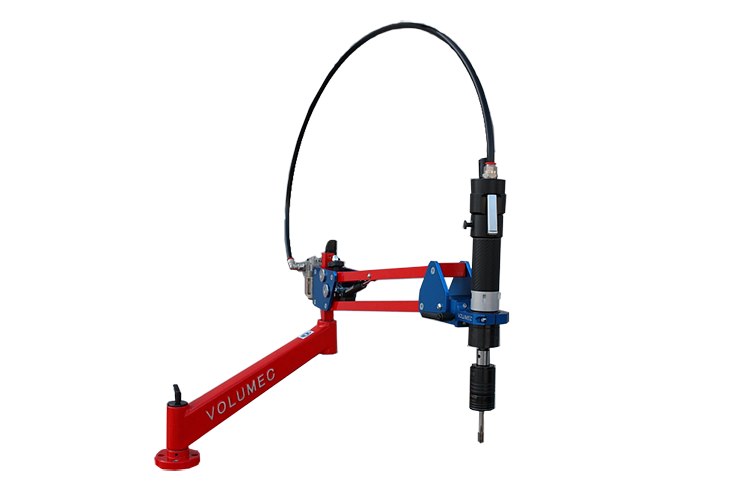

ET 350

FEATURES

Model

Tapping capacity on Steel (Metric)

Tapping capacity on Steel (Inches)

Torque at 6 bar (Nm)

No-load speed (rpm)

Weight (Kg)

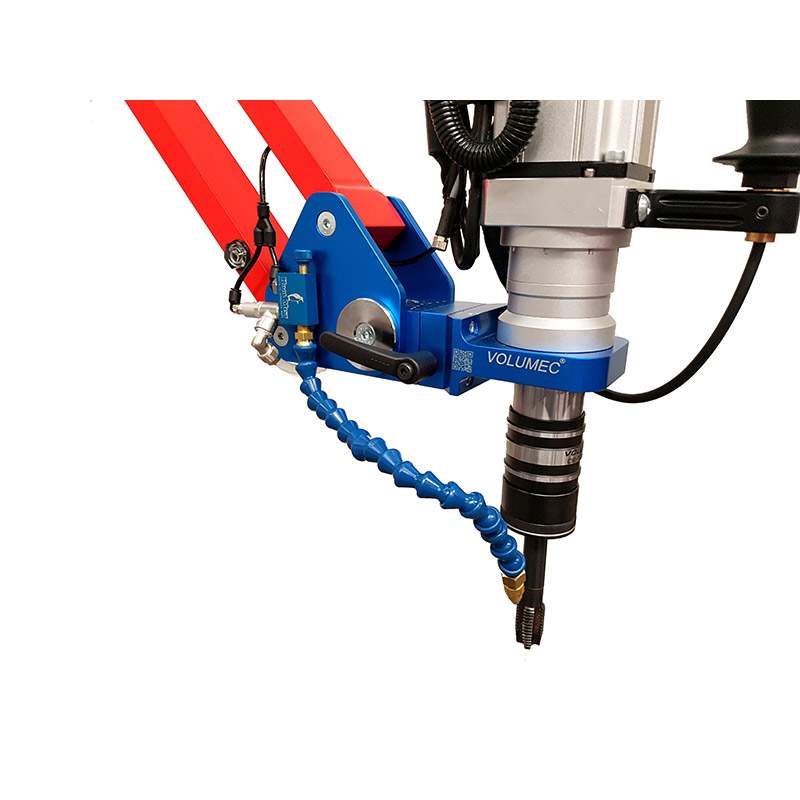

Spindle

ET 350

M3 - M12

1/8” - 1/12”

28

350

15

GR1

Add ET 350 to the estimate

ADD ACCESSORIES TO THE ESTIMATE

OPTIONAL

-

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M3 TO M12 (Ø19 mm)Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M3 TO M12 (Ø19 mm)Quick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M3 TO M12 (Ø31 mm)Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M3 TO M12 (Ø31 mm)Quick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M5 TO M20Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M5 TO M20Quick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageMPA 1/2 - MPA 1/4 - MPA 3/8Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageMPA 1/2 - MPA 1/4 - MPA 3/8Quick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M3 TO M20Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M3 TO M20Quick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageMPS10GR1 (Ø19 mm) for tools between Ø 0,5 and Ø 10 mm MPS13GR1 (Ø31 mm) for tools between Ø 1 and Ø 13 mm MPS10GR2 (Ø31 mm) for tools between Ø 0,5 and Ø 10 mm MPS13GR2 (Ø31 mm) for tools between Ø 1 and Ø 13 mmQuick view

Add to offer This product has multiple variants. The options may be chosen on the product pageMPS10GR1 (Ø19 mm) for tools between Ø 0,5 and Ø 10 mm MPS13GR1 (Ø31 mm) for tools between Ø 1 and Ø 13 mm MPS10GR2 (Ø31 mm) for tools between Ø 0,5 and Ø 10 mm MPS13GR2 (Ø31 mm) for tools between Ø 1 and Ø 13 mmQuick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageBMGR1 (Ø19 mm) BMGR2 (Ø31 mm)Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageBMGR1 (Ø19 mm) BMGR2 (Ø31 mm)Quick view -

800x600 mm (total weight 150 kg.) H= 830 mm (adjustable) Thickness of the working plane 30mm entirely in milled steel and t-slots interior bushes holderQuick view

-

850x750mm (total weight 65 kg.) H=870 mm Upper bull top Internal top with bushes holder 4 turning wheels – 2 with brakesQuick view

-

600x300 mm entirely in 30 mm milled steel and t-slotsQuick view

-

With 4 wheels, 2 with brake, lifting column h=2000mm. Controllable with electric or pneumatic screwdriver. Weight: 220 KgQuick view

-

Can be driven with an electric or pneumatic screwdriver. Weight 60 kg (132 lb)Quick view

-

30 mm base central arm support column = 1000 mm 4 turning wheels – 2 with brakes weight 150 kgQuick view