JOYTAP 2 mod. JT2500

FEATURES

Add Joytap JT2500 to the estimate

VASTC

Volumec Assisted Screwing-Tapping Control

All models of JOYTAP series can be equipped with touchscren system, with the following features:

TAPPING

SCREWING

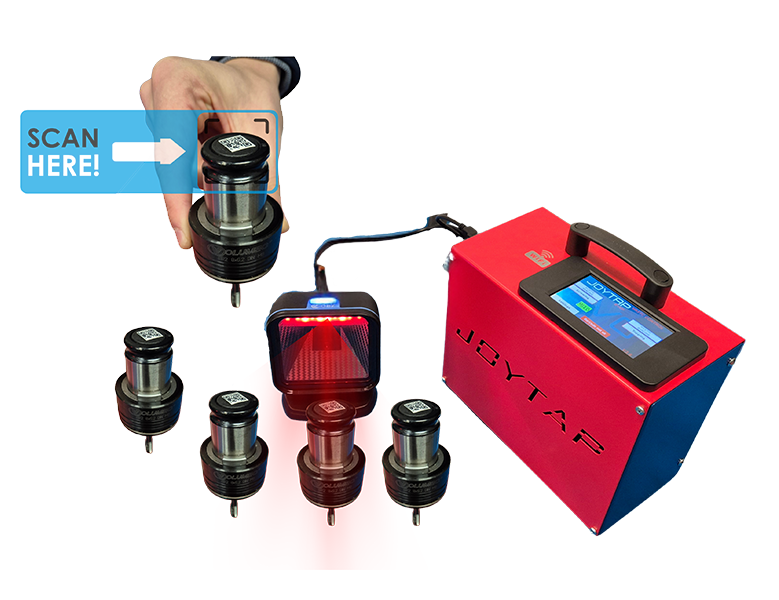

VASTC-SCAN

Optimization on work of efficiency and precision

SIMPLIFY AND REDUCE TIMES. Volumec provides a unique solution for your work: The VASTC system with an integrated QR code reader that identifies the different tapping and screwing tools.

The programs can be saved and associated with the relevant tool, the operator will only have to scan and the machine will automatically load the correct settings, significantly reducing the margins of error and processing times.

The VASTC SCANNER will automatically identify the corresponding work recipe for the various maschiature or screwings to be performed even on the same piece without the operator having to intervene to change the parameters.

In this way, the machining change process will be simplified and automated for both maschiatura and screwing operations, ensuring correct configuration and optimizing the efficiency of the work performed by the machine.

MAIN FEATURES

-

The VASTC scanner automatically recognizes the correct work recipe for various operations, without the need for manual intervention.

-

The process of changing operations for drilling and screwing is automated, ensuring correct configuration with every use.

ADVANTAGES

-

Eliminates the need to manually enter job settings for maschiatura and screwing.

-

Automatic loading of saved configurations associated with the QR code, without manual intervention.

-

Speed up the changeover process thanks to the immediate identification of the correct work recipe.

-

Minimization of potential human errors related to the manual setting of the various operations even in the presence of inexperienced operators.

-

Ensures execution with correct settings through automatic loading of configurations.

-

Prevention of configuration errors thanks to the correct association between QR code and work recipe.

In summary, using the scanner to read the QR codes of the maschiatura and screwing sockets with the VASTC system leads to an increase in efficiency, a reduction in downtime and the elimination of errors related to manual settings, overall improving the productivity and precision of the operations performed by the Joytap machine.

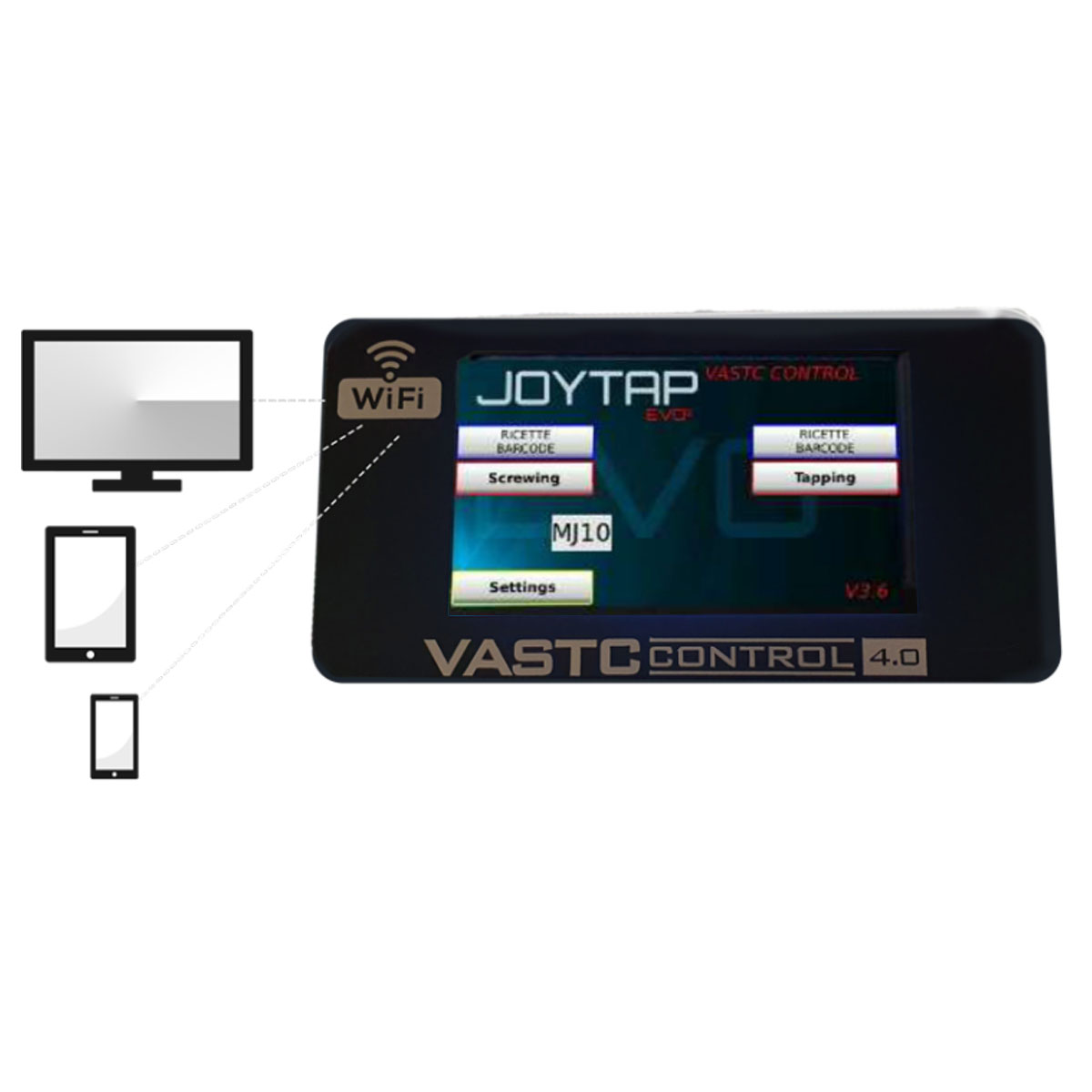

VASTC-4.0 (Industry 4.0) Wi-Fi

The New Vastc system 4.0 (assisted screwing tapping control), it has been equipped with Wifi connection, so that it can be controlled easy from smartphone, computer and/or tablets:

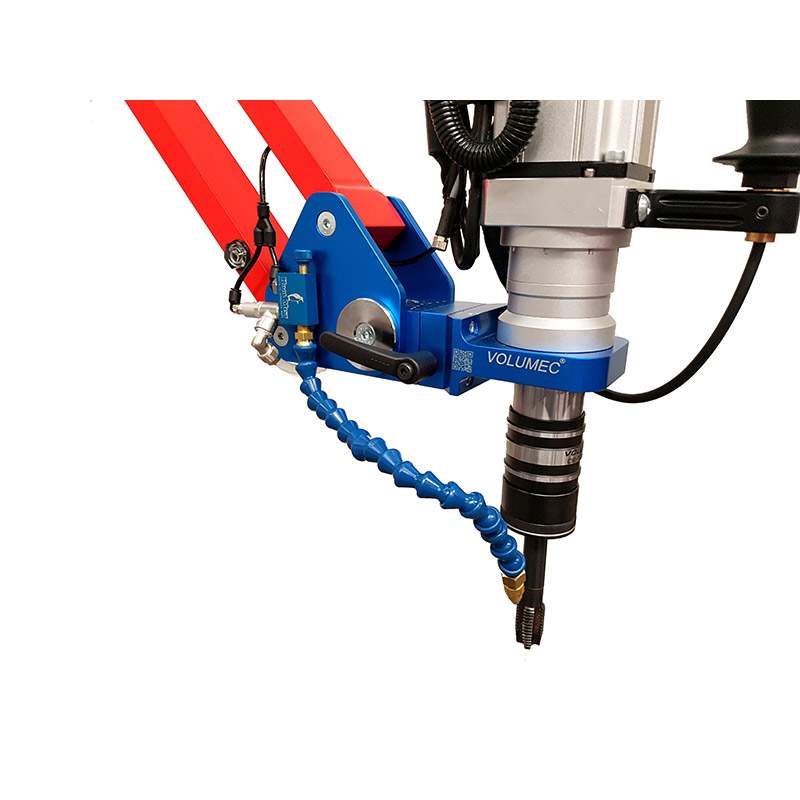

VASTC-1

VASTC control fixed on the engine.

ADD ACCESSORIES TO THE ESTIMATE

OPTIONALS

-

Add to offer This product has multiple variants. The options may be chosen on the product pageGR2 > GR1Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageGR2 > GR1Quick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M5 TO M27 (Ø31 mm)Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M5 TO M27 (Ø31 mm)Quick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M3 TO M30 (Ø31 mm)Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M3 TO M30 (Ø31 mm)Quick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M5 TO M20Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M5 TO M20Quick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageMPA 1/2 - MPA 1/4 - MPA 3/8Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageMPA 1/2 - MPA 1/4 - MPA 3/8Quick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M3 TO M20Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageFROM M3 TO M20Quick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageMPS10GR1 (Ø19 mm) for tools between Ø 0,5 and Ø 10 mm MPS13GR1 (Ø31 mm) for tools between Ø 1 and Ø 13 mm MPS10GR2 (Ø31 mm) for tools between Ø 0,5 and Ø 10 mm MPS13GR2 (Ø31 mm) for tools between Ø 1 and Ø 13 mmQuick view

Add to offer This product has multiple variants. The options may be chosen on the product pageMPS10GR1 (Ø19 mm) for tools between Ø 0,5 and Ø 10 mm MPS13GR1 (Ø31 mm) for tools between Ø 1 and Ø 13 mm MPS10GR2 (Ø31 mm) for tools between Ø 0,5 and Ø 10 mm MPS13GR2 (Ø31 mm) for tools between Ø 1 and Ø 13 mmQuick view -

Add to offer This product has multiple variants. The options may be chosen on the product pageBMGR1 (Ø19 mm) BMGR2 (Ø31 mm)Quick view

Add to offer This product has multiple variants. The options may be chosen on the product pageBMGR1 (Ø19 mm) BMGR2 (Ø31 mm)Quick view -

800x600 mm (total weight 150 kg.) H= 830 mm (adjustable) Thickness of the working plane 30mm entirely in milled steel and t-slots interior bushes holderQuick view

-

Con cave per staffaggio pezzi 800x640 h=870 mm Piano inferiore portaoggetti in acciaio, 4 ruote girevoli, 2 con freno. Peso: 55 KgQuick view

-

850x750mm (total weight 65 kg.) H=870 mm Upper bull top Internal top with bushes holder 4 turning wheels – 2 with brakesQuick view

-

600x300 mm entirely in 30 mm milled steel and t-slotsQuick view

-

With 4 wheels, 2 with brake, lifting column h=2000mm. Controllable with electric or pneumatic screwdriver. Weight: 220 KgQuick view

-

Can be driven with an electric or pneumatic screwdriver. Weight 60 kg (132 lb)Quick view

-

30 mm base central arm support column = 1000 mm 4 turning wheels – 2 with brakes weight 150 kgQuick view