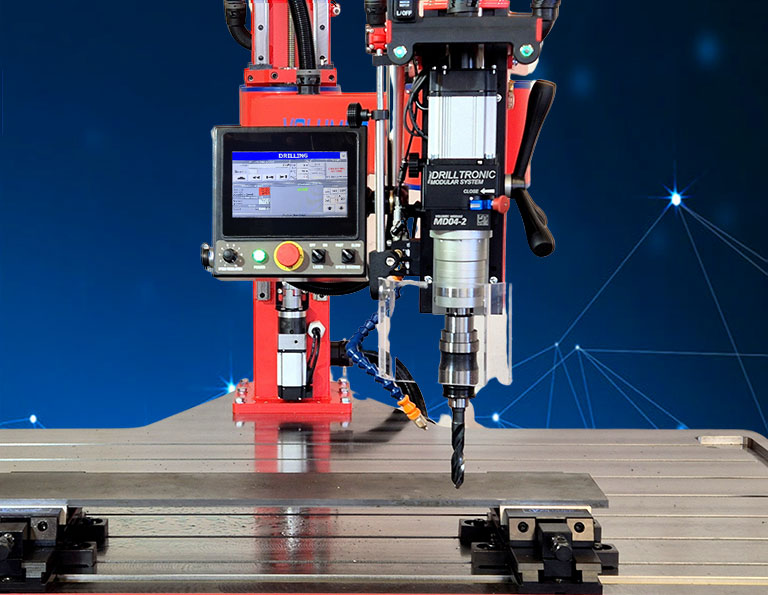

Drilling arms Drilltronic are essential tools in multiple industrial sectors, from mechanical production to material processing. Our drilling arms are designed to provide maximum processing flexibility, enabling precise drilling on various surfaces and materials, reducing error margins, and improving productivity. Volumec drilling arms are designed to provide smooth and fast positioning, ensuring rigidity and precision during drilling operations.

Drilltronic is not just the evolution of traditional or radial drilling but an arm suitable for small and large-scale production in multiple industrial sectors, from mechanical production to material processing. Drilltronic drilling arms are designed to be used by operators with no knowledge of CAD-CAM programming, in manual, semi-automatic, or fully automatic (CNC) modes. The fluidity and speed in positioning are guaranteed by high-quality mechanics that also ensure rigidity and precision during drilling-tapping, countersinking, and milling operations.

Types of Drilling Arms: Characteristics and Uses

Choosing the right drilling arms for your needs means investing in an optimized processing system where precision and safety are always guaranteed. Depending on your requirements, you can choose to purchase your drilling arm station in manual, semi-automatic, or CNC automatic versions.

Manual Drilling Arms

Manual (x/y) movement and locking of the arm, with manual drilling advancement (z).

Semi-Automatic Drilling Arms

Programming of work coordinates (x/y) with automatic locking of the arm through the VAPS control system, with automatic drilling and tapping advancement (VAPS-Z).

Automatic Drilling Arms – Full Auto CNC

Fully automatic and programmable positioning and drilling system (x/y/z) through the VAPS CNC control system. The new VAPS (Volumec® Assisted Positioning System) control system, with a touchscreen operator interface, allows for drilling and tapping operations at preset points, eliminating the need for manual tracing as with traditional drills.